through accurate benchmarking

indicators and performance based star ratings

transforming energy data into actionable intelligence

| Description | Standard Number | Regulation | Guideline | Progress |

|---|---|---|---|---|

| Compact Fluorescent Lamps (CFLs) | SLS 1225 | 1611/10 of 22ndJuly 2009 | Download | Mandatory energy label available. |

| Ceiling fans | SLS 1600 | 1794/15 of 22nd January 2013 | Download | Mandatory energy label available. |

| Ballasts | SLS 1200 | 1971/12 of 15thJune 2016 | Mandatory energy label available. | |

| Linear Fluorescent Lamps | SLS 1625 | 1971/12 of 15thJune 2016 | Mandatory energy label available. | |

| Refrigerators | SLS 1690 | N/A | Download | Voluntary labelling available |

| Air conditioners | SLS 1586 | N/A | Labelling programme is in progress | |

| Computers | SLS 1580 | N/A | Download | Labelling programme is in progress |

| LED | SLS 1530 | 2177/3 of 26th May 2020 | Download | Mandatory energy label available. |

| Electric Motors | SLS 1525 | N/A | Labelling programme is in progress |

Benchmarking is the practice of comparing the measured performance of a device, process, facility, or organisation to itself, its peers, or established norms, with the goal of informing and motivating performance improvement. When applied to energy use, benchmarking serves as a mechanism to measure energy performance of a single product or service over time. We have published energy consumption benchmarks for five key sectors. Based on survey inputs, targeting organisations to go for incremental levels of energy efficiency these benchmarks are revised, and the revised benchmarks are expected to be published this year. If a product or service performs lower than the standard, the benchmark offers a realistic energy goal. Then systematic energy management - establishing action plan, implementing strategies, monitoring energy consumption and continuous improvement - can be practiced.

Benchmarking is useful for state and local government property owners and facility operators, managers, and designers. It facilitates energy accounting, comparing a facility's energy use to similar facilities to assess opportunities for improvement, and quantifying / verifying energy savings. Currently benchmark regulation has been drafted for Finanacila and retail sector and will be gazette by 2022.

As per the energy consumption, the main sectors identified are: Industrial, Commercial, Domestic, Government Each main sector is catgorized into sub sectors according to the International Standard Industry Classification(ISIC). Each sub sector is identified by a 4 digit number. Portal Users can select their ISIC classification number at registration process.

EPI/Specific Energy Consumption Benchmark will be introduced to each subsector through the energy benchmark regulation and EPI/EPIs mandated by the regulation currently is as follows.

| Class | Group 471 - Retail sale in non-specialised stores |

|---|---|

| 4711 | Retail sale in non-specialised stores with food, beverages or tobacco predominating |

| 4719 | Other retail sale in non-specialised stores |

| Classified under Division 47 Retail trade, except of motor vehicles and motorcycles of ISIC, under Section G Wholesale and retail trade; repair of motor vehicles and motorcycles of the International Standard Industry Classification (Revision 4) of the united Nations | |

| Class | Group 641 - Monetary intermediation |

| 6411 | Central banking |

| 6419 | Other monetary intermediation |

| 6420 | Activities of holding companies |

| 6430 | Trusts, Funds and similar financial entities |

| Class | Group 649 - Other financial service activities, except insurance and pension funding activities |

| 6491 | Financial leasing |

| 6492 | Other credit granting |

| 6499 | Other financial service activities, except insurance and pension funding activities, not elsewhere classified |

| Classified under Division 64 Financial service activities, except insurance and pension funding of ISIC, under Section K Financial and Insurance Activities of the International Standard Industry Classification (Revision 4) of the United Nations | |

| Sub sector | ISIC classification No |

|---|---|

| Financial - Banking | 641 |

| Insuarance | 651 |

| Retail | 471 |

| Hotel | 551 |

| Commercial building | 701 |

| Government office | |

| Warehouses | 521 |

| Hospitals | 861 |

| Educational - Primary | 851 |

| Educational - Secondary | 852 |

| Educational - Higher | 853 |

| Tea | 107 |

| other plantations | 107 |

| Apparel & textile - Spinning, weaving and finishing textiles | 131 |

| Apparel & textile - Manufacture of other textiles | 139 |

| Apparel & textile - Manufacture wearing apparel -except fur apparel | 141 |

| Apparel & textile - Manufacture of articles of fur | 142 |

| Apparel & textile - Manufacture of knitted and crocheted apparel | 143 |

| Manufacture of leather related products | 151 |

| Manufacture of footwear | 152 |

As per the Specific Energy Consumption (SEC) reports of facilities, SLSEA award appropriate ratings to facilities, based on the level of energy performance of the relevant category of Facility according to the table of rating of energy performance of a Facility, as follows.

Star ratings of the mandated ISIC categories as per the regulation,

| Column i | Column ii |

|---|---|

| Specific Energy Use (SEU) kWh/m2 per year | Rating |

| SEU ≤ 90 | Five stars  |

| 90 < SEU ≤ 120 | Four stars  |

| 120 < SEU ≤ 140 | Three stars  |

| 140 < SEU ≤ 160 | Two stars  |

| 160 < SEU ≤ 180 | One stars  |

| SEU > 180 | Non compliance |

As per the Specific Energy Consumption (SEC) reports of facilities, SLSEA award appropriate ratings to facilities, based on the level of energy performance of the relevant category of Facility according to the table of rating of energy performance of a Facility.

Reducing and optimising energy consumption is key to both keeping overall energy costs down and meeting sustainability goals. Some of the largest cost reductions come from simple operational modifications that are low or no cost. From providing consulting services by answering queries, conducting awareness programmes upon request, and attending ISO 50001, we provide a host of services to assist industries, commercial and state sector institutes to tackle their energy related issues and projects.

We also assist in developing and implementing energy management programmes at provincial level.

Benchmarking is the practice of comparing the measured performance of an equipment, process, system, facility, or organisation to itself, its peers, or established norms, with the goal of informing and motivating performance improvement. When applied to energy use, benchmarking serves as a mechanism to measure energy performance of a single product or service over time.

Benchmarking has been recognized to be an effective analysis methodology and management tool that helps to improve efficiency and performance in many areas for different objectives.

Benchmark can be presented by ‘Specific Energy Consumption’ value for each sector which implies the amount of energy used per unit output of a product or service. Specific energy consumption (SEC) can be calculated as follows:

Specific Energy Consumption (SEC) = Amount of energy used for a particular period/ Amount of production or services provided in the same period

Unit of SEC can be varied for different sectors due to the variation in production and services in different sectors.

Energy benchmark regulation provides the standard benchmarks to be achieved by the facilities categorized according to the International Standard Industry Classification (ISIC) and as per the regulation such facilities must comply with the benchmark specified in the regulation.

If the Specific Energy Consumption of a Facility is reported to be at an unacceptable level above the SEC Benchmarks of the relevant category of the Facility as given in the regulation, the Facility Manager have to submit a detailed audit report and a plan of action on EEI&C to reduce the energy usage to an acceptable levels.

Energy efficiency measures can be implemented across various sectors to reduce energy consumption and improve overall sustainability. Here are some sector wise energy efficiency measures

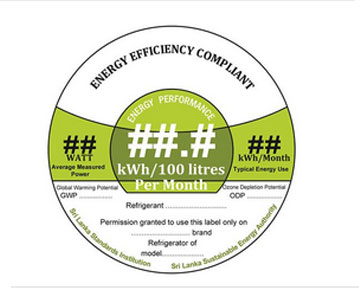

The energy efficiency of appliances and the efficient use of appliances are two major contributory factors for energy efficiency.

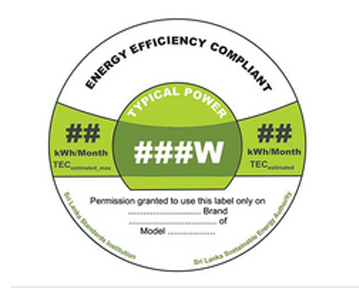

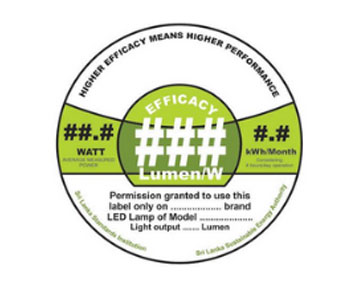

Typically, the Appliance Energy Labelling Programme uses one or more of the following complementary tools to improve the energy efficiency performance of appliances and equipment under the clauses 35 (d) and (e) of the Act:

Energy performance standards are available for Compact Fluorescent Lamps, Fluorescent lamp ballasts, LED lamps, Electric motors, refrigerators, room air conditioners and computers. In addition to these, publication of standards is in progress for LED modules (panel lights) electric water pumps, rice cookers, televisions and pedestal fans.

Regulations have been gazetted on mandatory energy labelling for CFLs,Ceiling fans and LED lamps. For computers and refrigerators, voluntary labelling programmes are in operation.

| Description | Standard Number | Regulation | Progress | Energy Labels |

|---|---|---|---|---|

| Compact Fluorescent Lamps (CFLs) | SLS 1225 | 1611/10 of 22nd July 2009 | Mandatory energy label available | |

| Ceiling fans | SLS 1600 | 1794/15 of 22nd January 2013 | Mandatory energy label available |  |

| Ballasts | SLS 1200 | 1971/13 of 15th June 2016 | Mandatory energy label available | |

| Linear Fluorescent Lamps | SLS 1625 | 1971/13 of 15th June 2016 | Mandatory energy label available |  |

| Refrigerators | SLS 1690 | N/A | Voluntary labelling available |  |

| Air conditioners | SLS 1586 | N/A | Labelling programme is in progress | |

| Computers | SLS 1580 | N/A | Labelling programme is in progress |  |

| LED Lamps | SLS 1530 | 2177/3 of 26th May 2020 | Mandatory energy label available. |  |

| Electric Motors | SLS 1525 | N/A | Labelling programme is in progress |

Tri-generation or Combined Cooling, Heat and Power (CCHP) refers to the simultaneous generation of electricity and useful heating and cooling from a single source of energy. In this case, 80% of the energy of the primary fuel can be utilised for tri-generation. This is one of the best methods available for maximum utilisation of energy. In this context, SLSEA has decided to explore the possibilities of introducing tri-generation in industries.

We have carried out a feasibility study in tri-generation for the hotel industry in 2015. As an outcome of this, it has been identified that there is a potential for implementing tri-generation systems in industrial zones. Purpose of this project is to explore the feasibility of implementation of such a system locally, and to train and create awareness on the concept of tri-generation among stakeholders. The feasibility studies are planned to be conducted in the Katunayake and Biyagama export processing zones. The project is being implemented in collaboration with the Industrial Services Bureau (ISB).

In practice, tri-generation can be used as the process by which some of the heat produced by a cogeneration plant can be diverted to generate chilled water for air conditioning or refrigeration. An absorption chiller is linked to the combined heat and power plant to provide this functionality.

There are several benefits to tri-generation including:

As such we are exploring the possibilities of introducing tri-generation for sectors such as hotels, textile and apparel and industrial zones.

Final report of the feasibility study is presented, showcasing the virtues of a central thermal energy supply utility for industrial zones with added on-site power generation capability. Main contents of the report are Background data including Energy Survey, Details of the Factories selected for the survey, Energy Consumption Scenario at Biyagama Export Processing Zone (BEPZ), Combine Cooling Heating and Power (CCHP) Technology, Changes needed for the Energy Consumption at BEPZ, Proposed Tri-generation Architecture for BEPZ including detailed Technical and Financial Feasibility and Sensitivity Analysis , Evaluation of Technologies.

Design & Developed By Procons Infotech.

Construction Registration

Construction Registration Energy Auditor Registration

Energy Auditor Registration